“We wanted to offer

people more options,

with a range of angles

from 10° to 25°”

explains Julian Ruf,

R&D Director at HORL ®.

Development of the HORL ®3 Pro Angle Support

On the surface, the only apparent differences between the HORL ®3 Pro Angle Support and those for our other models of sharpener are its dark bronze colour and its material. But on the inside, there is an ingenious mechanism that allows you to select six different grinding angles. It took over a year of research and development to create. What was the journey like, from initial idea to finished product?

explains Julian Ruf,

R&D Director at HORL ®.

Our starting point was to develop an angle support with greater flexibility and much wider possibilities. While working on our ideas, we asked ourselves: What is the best way to enable six grinding angles?

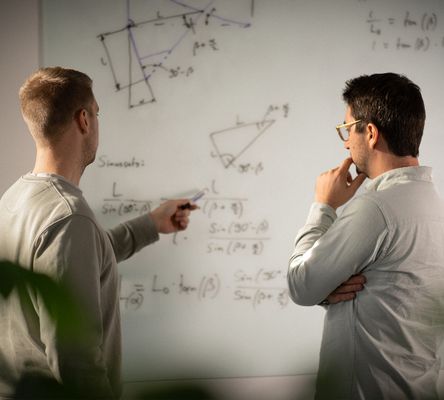

Turning, pushing, squeezing... we came up with many ways to adjust the grinding angle. In the early concept stages, all ideas were considered, without regard to budget constraints. “Creativity is given priority,” says Julian. The focus is on user-friendliness, and our job is to reduce complexity as much as possible. With these design requirements in mind, the team works its way forward step by step. Until one idea inspires everyone: locking positions are designed inside the angle support with a slider control on the underside to ensure effortless angle adjustment – an innovative solution that remains hidden at first glance.

As a next step, our engineers transform the idea into a concrete draft design. CAD programs are used to create detailed 3D models and technical drawings of the angle support. The team then calculates the sizes of individual components and considers what materials are best suited for each of them. “We start testing early on, in order to confirm we have the right materials and find out whether our approach is feasible in practice,” explains Julian. At the end of this concept phase, the first prototype is created. And then it's time to try sharpening knives with it!

The HORL ®3 Pro Angle Support prototype is tested with knives of differing degrees of hardness. This is because its 22° and 25° grinding angles are designed to provide more stable results when grinding outdoor knives made of tough steel. Whereas the extremely narrow angles of 13° and 10° allow especially fine blades made of hardened steel to be ground to an ultra-fine edge.

In parallel with functional testing, the materials of the inner workings of the prototype are also tested thoroughly. “We rely on endurance testing to confirm this. The locking function is tested thousands of times on a special rig,” explains Julian. “This allows us to ensure that the materials meet our high standards for long service life.” As well as functionality and durability, usability aspects are examined at this stage to ensure it has a pleasant sound and feels good in the hand. Here, too, nothing is left to chance.

Beyond the HORL ® laboratory, field tests are conducted with users. Julian points out a comprehensive tabulation of results gathered for evaluation. “We try to get the widest possible range of feedback: for example, from people with a lot of strength and people with little strength, people who are technically savvy and people who are not. This helps us to assess whether people find the angle adjustment mechanism intuitive and easy to use.”

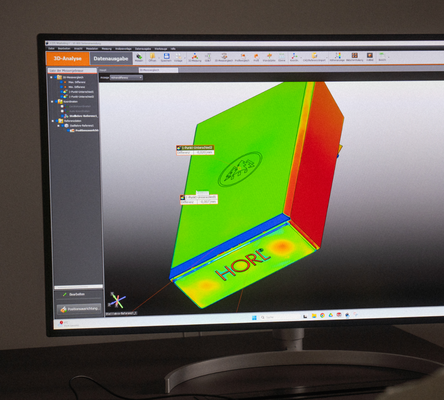

Once testing of the prototypes has been completed, the HORL ®3 Pro Angle Support is prepared for series production. During manufacturing, every hundredth of a millimetre is important in ensuring knives are ultimately sharpened at the precise angle. Julian takes us into the metrology lab: “For precise measurements we use instruments made by Keyence, such as this microscope and laser scanner.” In the production facilities themselves, every step is checked again to ensure that the dimensions remain accurate. This is how we make sure that every HORL ®3 Pro Angle Support meets our standards of high quality.

“Our work isn’t over once a product is ready for series production,” reminds Julian. “We spend 10 to 15 percent of our time supporting production.” Nevertheless, when the first customers hold the finished product in their hands, a huge milestone has been reached. It was another particularly emotional moment for us when the HORL3 Pro was awarded the prestigious iF Design Award for innovative product design.

Julian Ruf looks back on winning the

iF Design Awards for the HORL ® Scissors

and the HORL ®3 Pro.

“It gave us one of the best feelings we’ve ever had - after working on something for 14 months to receive such recognition.” A wonderful boost as we look forward to turning the next big ideas into innovative products.